The five most commonly used installation methods for splicing screens! easy and convenient

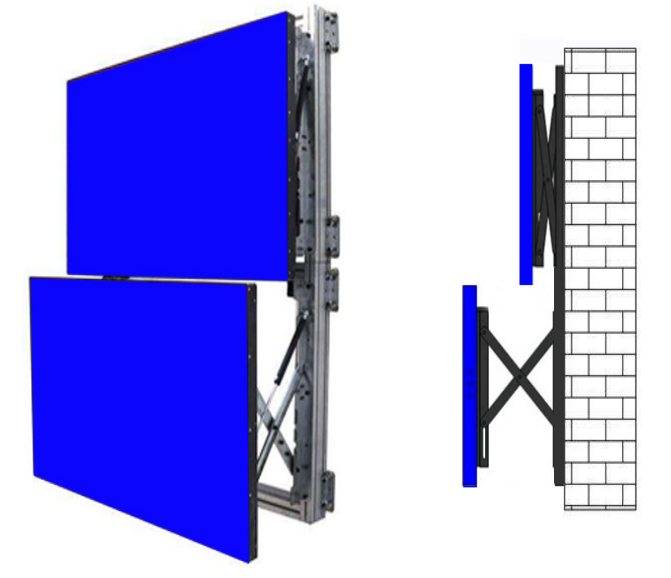

Hydraulic front maintenance bracket installation:

The hydraulic front maintenance bracket of the LCD splicing screen can be maintained from the front by pressing the screen during maintenance. The front maintenance method removes the screen in front of the LCD video wall, and then maintains it. This installation method is simple and direct, and it is also easy to disassemble for later after-sales. It is currently the most used installation method.

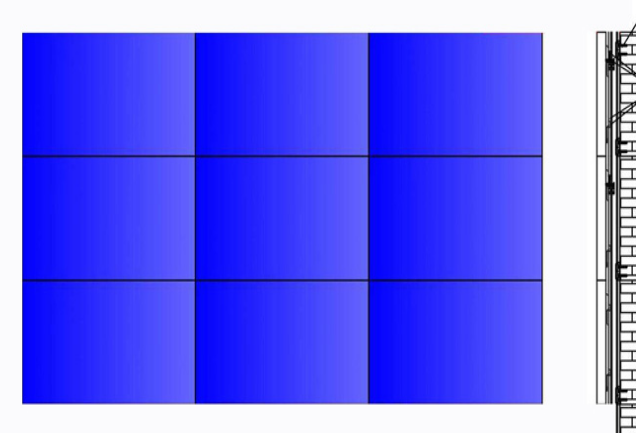

Wall Mounting Method:

Wall-mounted bracket installation is to use expansion bolts to first fix the bracket on the wall, then hang the LCD splicing screen on it, and then debug it, and the installation is simple and fast. However, if the number of LCD video wall displays is large, the wall may not be able to carry it.

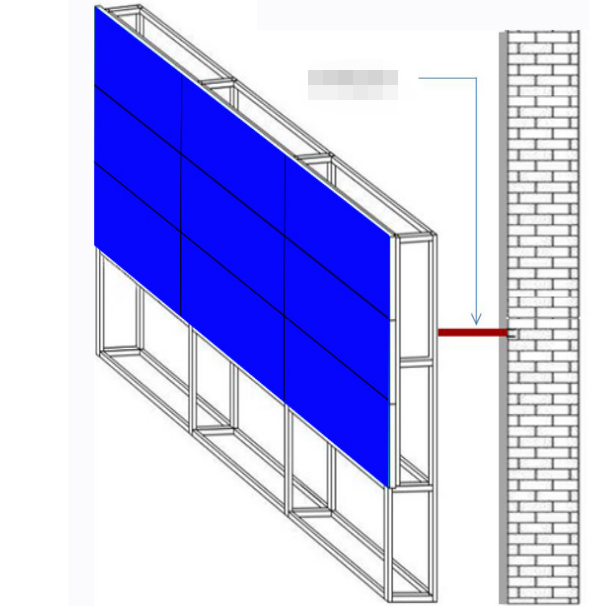

Floor stand installation method:

In the method of floor stand installation, the entire LCD screen system is supported by the bracket, and the splicing bracket must support the weight of the entire system. This installation method requires that the ground to be installed is flat, the ground is strong enough, and the requirements for the splicing bracket are relatively high, so the installation is conducive to the maintenance and fault repair of the system.

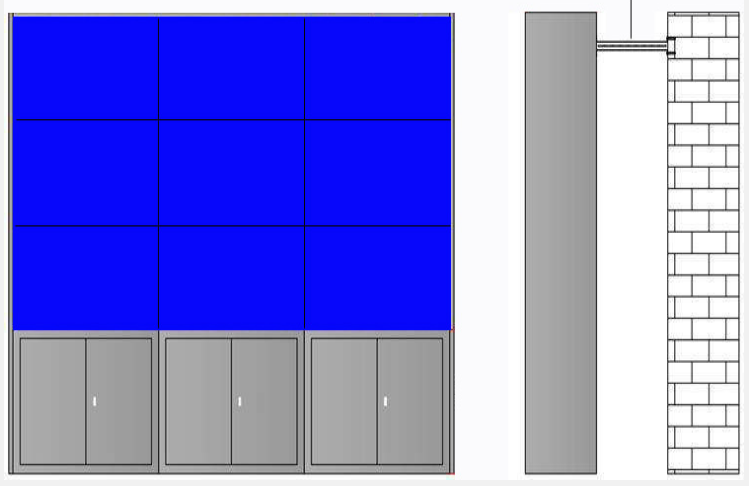

LCD video wall floor cabinet installation method:

The floor-mounted cabinet installation is made of all-steel, computer gray appearance, plus electrostatic protection, the whole system looks beautiful and atmospheric, and the system is relatively simple if the LCD splicing screen needs to be moved.

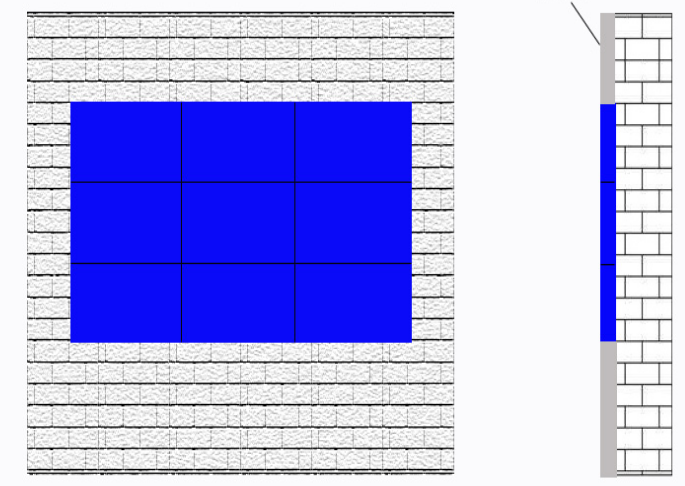

Video wall screen embedded installation:

Embedded installation is to dig out a space on the wall, and then wrap the screen. The advantage is that it can be better integrated with the surrounding environment and can save more space.